|

| |

|

|

|

|

|

|

| Without materials development as the starting point, a wealth

of new features and quality products will never come into being. As a developer

and manufacturer of resin and composite materials, we have been responsible for

the production of many new materials. |

| Resin molding with self-developed

materials excelling in heat resistance and strength.

Resin molding with self-developed materials excelling in heat resistance and strength.

These materials have been developed as substitutes for vinyl chloride and other

elastomeric material*.

Using PET as the basic material, we can freely make adjustments to give the material

a soft texture like leather or soft vinyl chloride, and in terms of resistance

to abrasion and elastic strength, it compares favorably with vinyl chloride. The

material also has heat resistance qualities superior to other elastomeric materials.

*Soft plastics such as EXA, EPAM, TPO |

|

|

An environmentally-friendly alternative to vinyl chloride. |

|

The hardness (adjustment of hardness) can be performed

at will. |

|

|

The materials can be recycled. |

|

The materials are capable of sheet molding and injection molding. |

|

|

| |

|

| Molded parts

|

Sheets |

| Many kinds of molded parts can be produced having superb flexibility even

with recycled PET material. |

These can be processed in various degrees of thickness, flexibility, colors,

and transparency, so have a range of applications including insulation coatings

and shock absorption material. |

|

| Urethane can be applied

as coating onto the surface of foam material.

Coating on the surface of foam material used to be impossible due to the coating

seeping into the material, but it can now be achieved using aqueous urethane coating. |

|

|

Can be used to coat even porous surfaces. |

|

Since it uses aqueous coating, it causes less harm to the environment

and human health than products containing thinner. |

|

|

We offer a selection of soft or hard films, and they are difficult

to break. |

|

|

|

|

| Uses include protective coating

for children's toys and sofa material. |

|

| |

|

| The coating does not seep even

into porous sponge material, and can be used to coat just the surface. |

Even on cylindrical objects, the

coating surface does not break, and since it is highly weatherproof, it can be

used outside as well.

|

|

|

|

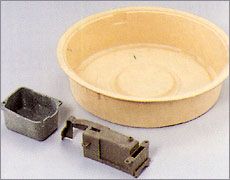

Injection molded parts using

waste paper

These products combine paper material with a special kind of

resin, restricting combustion to 5000 calories. |

|

|

|

Development, manufacture and

sale of high-density resin

We have developed plastic material that has the same density

as steel, and by making molding easy, we have been able to produce loudspeakers

with high audio quality at low cost. |

|

|

|

Development, manufacture and

sale of powder coating

Coating materials (for fluidized bed coating and electrostatic

coating) that excel in terms of shockproof properties, anti-adhesiveness and luster.

Since we develop them ourselves, we are able to offer them at very reasonable

prices. |

|

|

|

|

|

|

|